" I was looking at your blog, checking out the axes etc. When I was at the British museum last summer, I saw a well- corroded broadaxe very similar to the bayuex broadaxe, and it looked like they had forged it in a quite slick way. ...

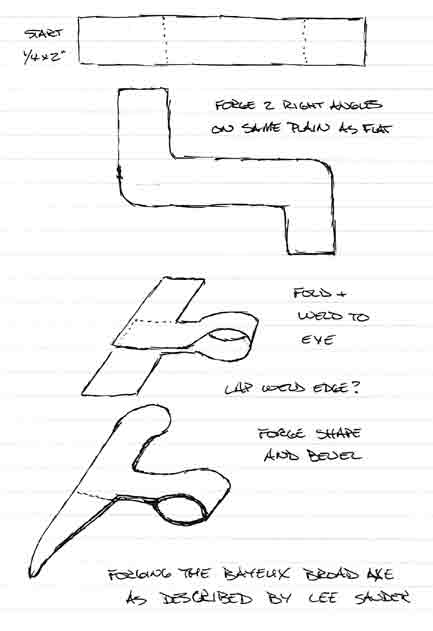

This is a little hard to describe without sketching, but here goes. The body and wings were all forged of a single piece, I don't remember whether there was a separate steel edge, I don't think so though. It looks like they took a sinlge long piece of stout flat bar. Mark into quarters. Make a right angle edge bend, at the first quarter mark. Turn it over, make another rt angle edge bend at the opposite end, going the oyther direction. So now you have a kind of straight N shaped piece, or two L's joined in trhe middle. Then bend one the flat in the center, which forms the eye, the remainder of the flat- to flat center section is welded together for the shaft, and you have the two edge bends lined up to form the wings of the axe, just like that! You can see how this solves several problems- the grain of the iron is continuous, there's no single weld across the stress point of the T, you get a nice generous fillet at that T since there's double the metal there.

Clear as mud, I know. So basically, your set up is the shape of two L's joined at the top- the short leg of the L's point in opposite directions. When you fold it in the center, it's now a T.

I thought this was pretty sexy, and a great example of how our contemporary thinking is confused from working steel, without the habit of considering the diection of the slag stringers.

I've attached a picture. It doesn't show up that well here, but I'm pretty convinced this is how they did both of these ... "

One of the books I came home from Denmark with was 'Roar Edge - Skuldelev 3 skibet som arkaeologisk eksperiment' by Anderson / Crumlin-Pedersen / Vadstup / Vinner (Vinkingeskibshallen i Roaskilde - 1997). The volume is unfortunately in Danish, but details the reconstruction project of the Skuldelev 3 ship, the Roar Ege. The book is crammed with very clear line drawings of all the timbers, plus the construction methods that were used.

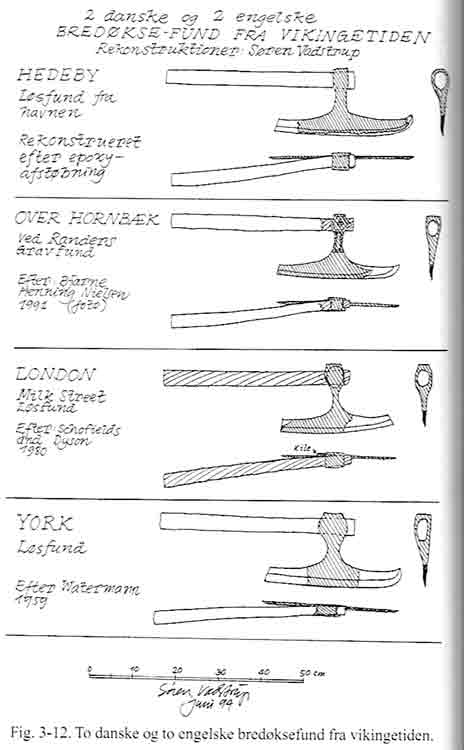

I was visiting with a bunch of friends over the weekend. One of the guys is very into small boats (Scott - he has a small lapstrake sailboat), so I had hauled along a couple of the books I had bought in Denmark. I was up before everyone else Sunday morning, so started looking through that volume. ( I have hardly cracked any of the books I brought back!) There was a whole chapter on tools, including a number of drawings of this specific T broad axe. They reference four samples, including the one from London that Lee had also provided the excellent image of. You can clearly see the weld line in that image too!

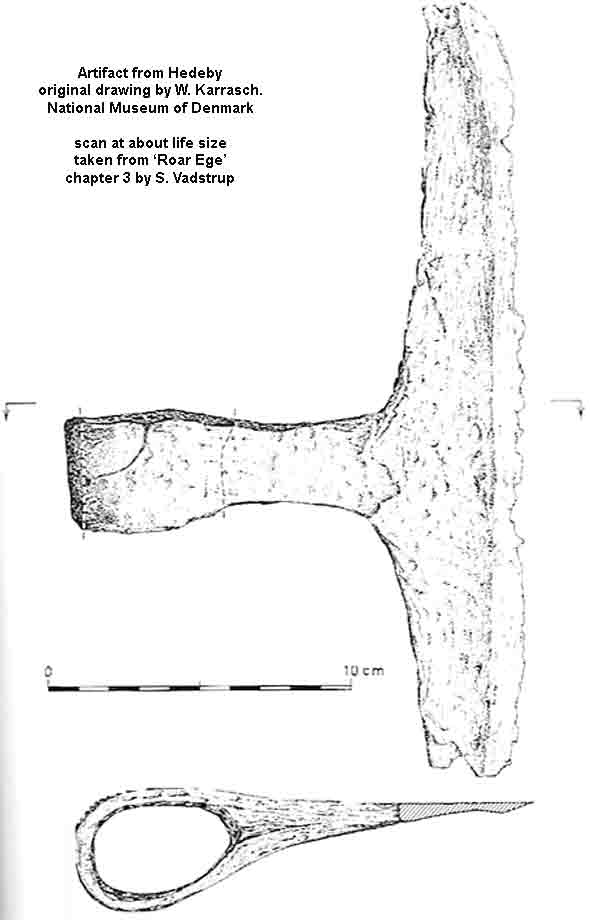

In the book there was this detail drawning of a broad axe from Hedeby in Sweden. The construction there appears to show a third method of constuction. One folded strip for the eye has been wrapped and then welded to the centre of a longer piece set at right angles (if I'm reading the drawing correctly).

The cross sections shown for the remaining two artifacts make them look like punched eyes like the method I had used. (Almost all the axes I saw in Denmark were punched eyes.)

Of course all this excellent reference material did not show itself until AFTER I had finished my reconstruction. I was happy to see that the artifact broad axes all show a cant to the handle that moves the hands out of the plane of the cutting edge. I had done this on my own version without a specific reference.

The method observed by Lee is certainly an elegant solution to the metal forming problem posed by the shape of the T broadaxe, most especially as it takes into account the grain strength requirements imposed by the historic use of bloomery wrought iron by the Norse.

I wish I could say that my solution was borne of knowledge, even though it appears to mimic that used on some of the artifact samples. The truth is that this was just the only way I could come up with of combining a thick block required to punch out an eye with the overall shape of the finished tool. I suspect that my method of using a complete centre layer of carbon steel would NOT have been the one used in the Viking Age. Most typical (if a hard cutting edge was used at all) would be a simple lap weld. This uses less of the hard steel.

'Life imitates Art'

No comments:

Post a Comment