The question: Darrell, did setting up your forge affect your house insurance?

Did you have any problems with your insurance and if so, how did you fix them?

I want to set up my drive-shed as a forge, but for the last few days I’ve been worrying about my house insurance and whether that will prevent me for doing what I want.

DON'T ASK - DON'T TELL

Not in your wildest dreams should you consider telling your insurance company - or any one else remotely official - about your forge. Even if you are professional, (like I am), do NOT tell any authorities what you are doing!

Forge work is normally grouped in with foundry work in the minds of 'the authorities' - which means a HEAVY INDUSTRIAL classification. The ramifications of this are immense - and fatal to your operation. How is your property actually zoned?

Concider the requirement on environmental equipment if those clowns get wind.

There was a situation a couple of years back with a teenager who had taken a couple of courses with me, and showed considerable promise as a young smith. He had applied and received one of those Ontario 'teen small business start up' grants. This comes with an advisor to administrate the funding and process. That person, acting in good faith (but some lack of insight), had suggested that the Ministry of Environment be contacted about the operation. The result was a requirement for a full scale Environmental Impact Assessment - a process identical to the one major industrial concerns (steel mills like Stelco or Defasco) have to undertake. A rough price tag of $5000. Needless to say, it killed this 16 year olds plans to make candle holders in his back yard!

Now one thing you MIGHT try - is the dodge I am now personally using here. In recent conversations with my own insurance company (about coverage for computers), I have gotten a special addition to my home owners as a 'Home based business' , defined as a 'self employed artist'. This costs me $140 per year on my main policy. It covers me for $25 K on tools, gives me an extra $2 M liability, coverage for stock at shows.

What a couple of friends of mine who work in the insurance business have repeatedly told me is : ACCEPT THE RISK.

In short, if you end up burning down the forge building, just take the loss and pay for the damage.

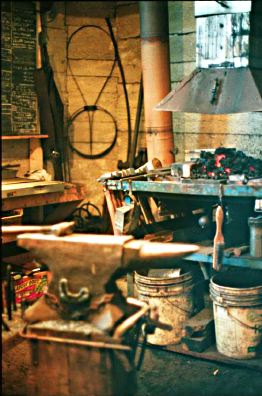

The forge is actually pretty darn safe. You basicaly NEVER leave the fire when its running - and its only when the forge is lit that there is any possible fire damage anyway. The whole set up is designed to safely contain the fire in the first place. Here at Wareham, the cutting torches and the propane space heater are a LOT more risky than the actual forge itself is.

My serious advice is to consider the set up of your equipment, and when in doubt stick extra brick or sheet steel around areas that may be possible fire points.

The floor under the forge itself is made of concrete paving slab and brick on dirt. The rear exterior wall is concrete. I have put up studs and insulation on this surface, but used sheet steel to cover the walls around the forge.

Regular Readers : You may have noticed that the past month has contained a slide towards fine arts away from the more usual technical subjects. This is a reflection of my own August art show involvement. I'm back into the forge now, and we return you to your regularly scheduled programing...

No comments:

Post a Comment