(or 'If first you don't succeed...')

DARC undertakes its annual fall smelt the weekend following Halloween each year. Although we are starting background research (on clay bodies) to return to our Hals / Icelandic series, we really did not have enough time from lab report through commercial sources to mount anything useful. I also wanted to give the 'Celtic Iron Age'* slag pit system one more try - this time with a half decent ore!

|

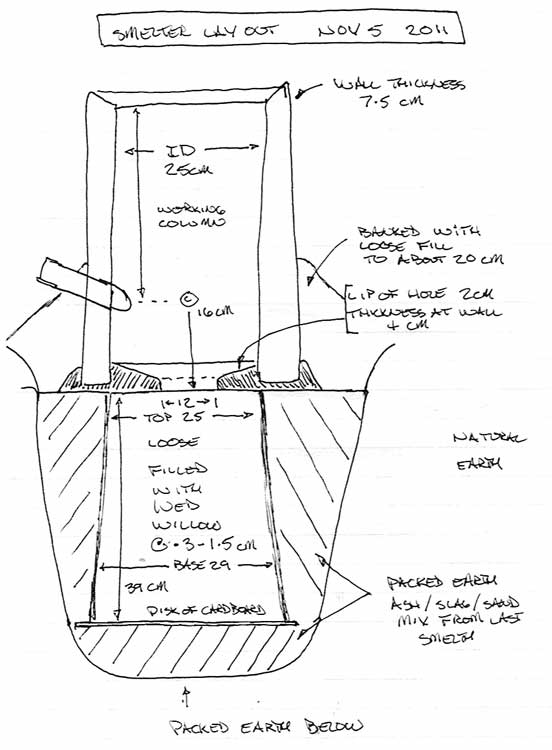

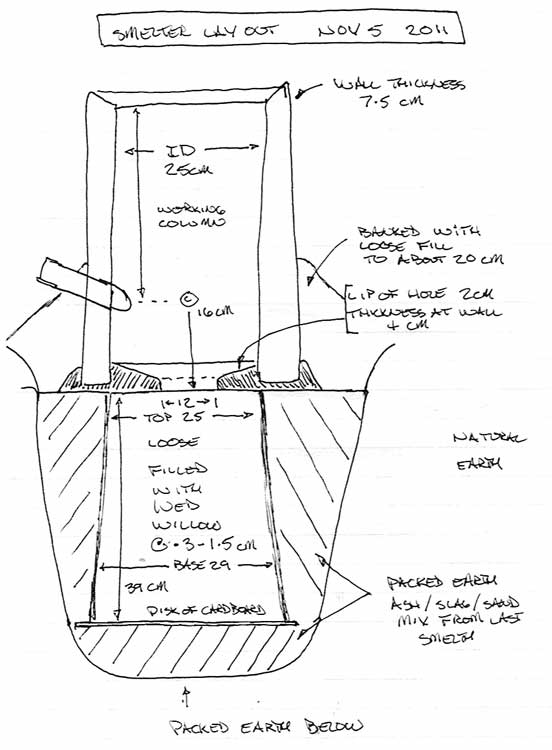

| Furnace Layout |

Part of the utility here is that we were able to save the actual furnace from the last smelt with minimal damage. The primary set up work (I thought) was going to be in building the pit portion of the set up. As you can see from the layout, this consisted of digging out the loose packing from the last smelt, then planting in another plastic pail.

A note to other experimenters: Although the original idea for using the plastic pail was based on simple ease and speed, in retrospect this proves an excellent method. The pails are standard - and easily acquired. As we found out from our last experiment, one holds about 40 kg of slag.

|

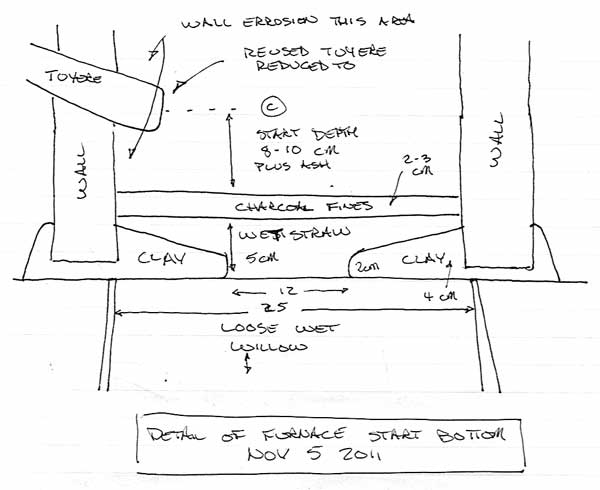

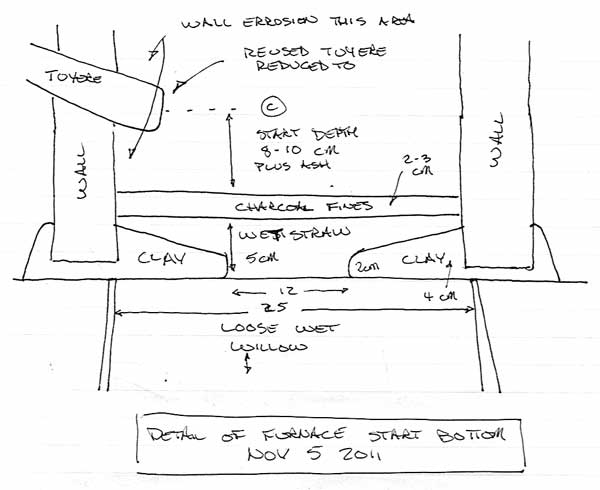

| Detail of Base Layout |

Acting on some advise from

Lee Sauder (and after looking again at the work of others and the archaeology), I have placed a 'donut' of clay at the base of the furnace, to constrict the movement of slag into the pit. Based as much as what I had on hand, this material is a mixture of clay with about 50% charcoal fines. The sticks packing the pit are also much less uniform than those used on

October's experiment. Here I did not trim off the smaller side twigs from the lengths. These were also cut from some branches I had soaking for a month in the pond (hoping to sprout them). Again, I will use the wet straw as a pad at the bottom, which worked extremely well last time. If I have any concern with this layout, it is that the space below tuyere level is going to be reduced to about 8 - 10 cm, which I think is going to prove a bit tight. Balanced against this is that the clay plug is very thin, and can easily be poked through with a rod from the top of the furnace.

|

| View down inside the furnace - showing the clay donut. |

|

| | | |

|

The furnace was generally in good shape, although there had been some construction problems originally that did lead to some cracking. Not surprisingly, the thing weighs some 50 kg +, and is bloody awkward to move for one person! The net result was even more piece breaking off and needing patching.

|

| Completed furnace |

The extend of the breakage and repair work can be seen via the colours on the surface. The spotty grey material is new clay that was added to patch in some of the pieces. The very red coloured clay here is the original furnace surface. You can also see several of the loops of heavy fencing wire I bound around the body 'just in case'. Expecting some problems with venting via these cracks, I have buried the bottom 20 cm or so of the furnace with loose packing (mix of dirt, sand, ash & slag fragments) left over from past smelts. This material is slightly damp via the rain we had earlier in the week. You can see that I have shored up the front wall with a double row of house bricks. (The plastic bucket lid was just temporary for over night.)

As ore was the primary reason for lack of a bloom last time, a better quality ore is certainly indicated for this experiment. There are three possibilities (easily) on hand:

Industrial Taconite

Gromps from past smelts

Forge scale sweepings

For now, the plan is to use the half pail of taconite (given by

Mark Puigmarti), a total of 21 kg. This material appears pre roasted (black colour and mildly magnetic). It is untested, and the actual iron content is unknown (although normally this type of material is in the 65 % Fe range). This quantity is enough for a small to medium bloom - estimated in the 5 + kg range. If anything, it may prove a bit 'dry' for the best use of a slag pit furnace.

Wish us luck!

(at least we *think* we know what we are doing!)

* For those sticklers for absolute historic accuracy:

I'm referring to this series as

'Celtic Iron Age' primarily because of the end use of this series. This a potential full working demonstration at the

Earth, Air Celtic Festival in August 2012. Yes, I realize we are really sticking a Viking Age short shaft over a pit, which really is not the same as the know Celtic Iron Age furnaces. Bare with me - this is still early days with this experimental series! (Working from what is known to work back towards a more accurate duplication of a possible historic method.)

No comments:

Post a Comment