The assembled team, after the smelt.

The assembled team, after the smelt.L to R : Darrell / Dave / Mark / Richard / (Paul standing in for missing Jake)

Front : Ken / Jessica

This is the equipment set up, seen the evening before the smelt.

This is the equipment set up, seen the evening before the smelt.Work took place inside the reconstructed 'Furnace Hut', set inside the Encampment compound.

The interior size, like the historic location, is roughly 2.5 metres wide by about three metres deep.

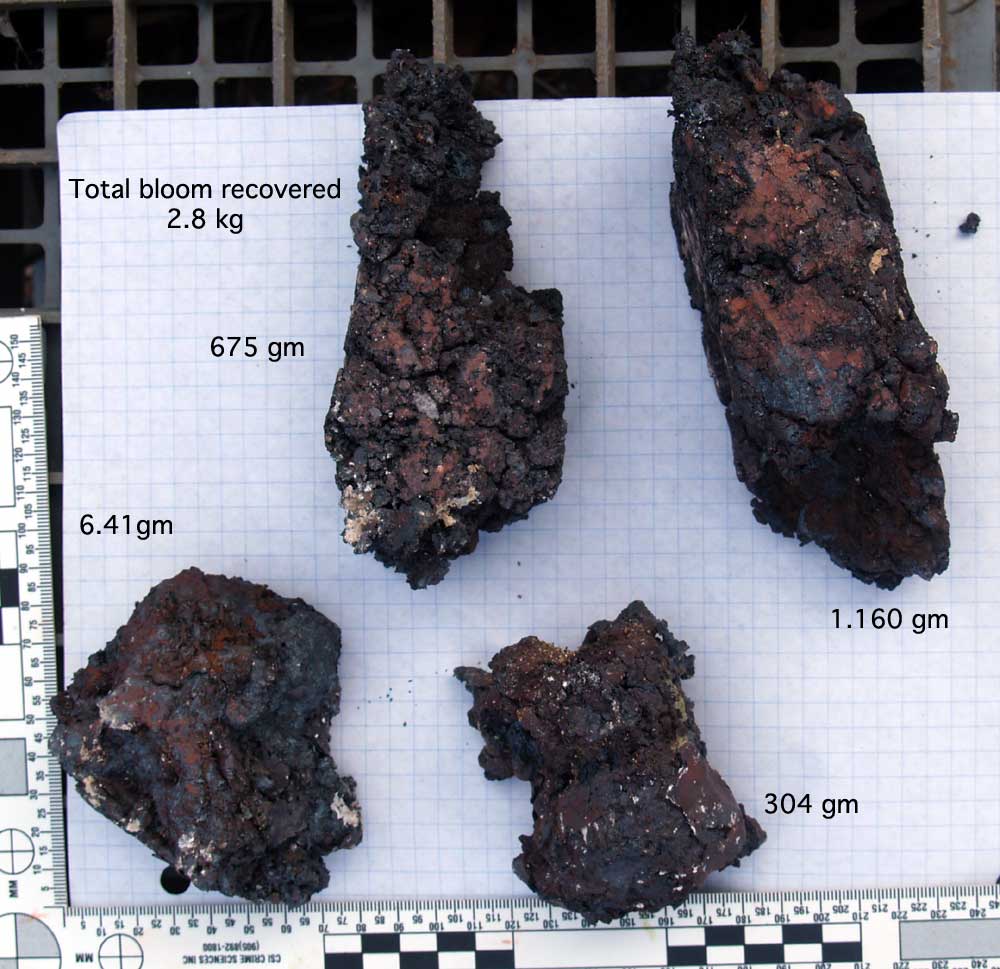

The results. The larger bloom broke up into four smaller fragments during the initial consolidation.

Total weight : 2.8 kg (This image roughly life size)

Total weight : 2.8 kg (This image roughly life size)

This is an image of the working area the morning after the smelt.

A careful comparison will be made to match this debris field with what what actually found in the archaeological remains.

A careful comparison will be made to match this debris field with what what actually found in the archaeological remains.

In a nut shell, our results parallelled what the archaeologists estimate the Norse did originally:

| ITEM | NORSE | DARC |

| Ore | local bog ore | DARC Dirt 2 analog |

| Amount | 18 kg estimated | 20 kg |

| Yield | 3 kg estimated | 2.8 kg |

| Charcoal | ?? - local softwoods | 35.5 kg hardwood |

| Time | ?? | 6 hours total |

I was extremely pleased with the overall progress of the smelt. At the very least, this marks only the second time in 1000 years that bloomery iron was produced in Vinland!

(Addition)

The larger bloom fragment was spark tested with an angle grinder. The result looked like a low carbon iron (red to dull orange with little feather).

Mark Pilgrim took the smaller dense fragment (640 gm) and reduced it down to a working block. Result was about 440 gm (so roughly 30 % loss to bar). He did report he had a lot of trouble with the bar cracking while he was working it. My first guess would be brittleness due to phosphorus - but with an analog used as ore, there should have been no phosphorus available. (??? Needs smarter heads than mine!)

Neil pointed out the error on the bloom photo - with incorrectly added decimal points. All in full grams!

No comments:

Post a Comment