Background:

Earlier in the year, I had been contacted by Amy West of Worcester State College in Massachusetts (

www.worcester.edu) . She was interested in setting a special project for her first year students in the 'Exploring the Vikings' course. In the end she also approached a number of experienced re-enactors I had suggested. Included in the interview group was Neil Peterson and Meghan Roberts of DARC. The students worked in small groups, each group submitting a number of questions (via e-mail) to one of the re-enactors. These are the questions I was asked - and the answers given. They may prove of some interest to my readers.

Eric Gustafson was my interviewer

> Also, please feel free to elaborate beyond what the question

> initally asks, any more information you can include is very welcome.

Eric et All:

Ha! Careful what you wish for. I have the bad habit of many historic interpreters, trying to anticipate the core of a question and working through from the background. Makes many things into mini lectures...

The Answers (and issues)

> 1. How long have you been doing Viking (Age) re-enactment? How

> old were you when you began?

I started with historic re-enactment in about 1976. Originally I got involved with the Society for Creative Anachronism, where the persona / character I chose was 'loosely based' on the Viking Age. I say loosely, as the SCA back in those days (and still today) includes as much fantasy as history. I would have been about 21 at the time.

After art school, I got a job working at a Settlement Era (1850's) living history museum. This greatly changed my concepts about re-enacting. Over the next decade, I became more and more impatient with the lack of actual history inside the SCA. Into the late 1980's I started to organize informal discussions about applying methods and concepts from other historic re-enactment groups (of all time periods) plus aspects taken from actual museum programs, into a more historically accurate method of presenting the Viking Age particularly.

My involvement in direct museum work related to the Viking Age is covered in question 8. (I can claim to be a 'professional' in living history.)

In 2000 year, this work would result in my invitation (as the only Canadians) to participate in the Norstead 'Grand Encampment' program (A special event including amateur re-enactors, for which I had written the original concept paper.) Problem was, at the time I actually did not have a team! I contacted those who had been talking about increasing the level of historic accuracy inside the SCA, plus a number of people I knew who had done serious work inside a Viking Age framework. To this I specifically invited a small number of people from the roughly 1000 members of the SCA in Ontario, those who I knew to be excellent living history interpreters (mostly not centered on Viking Age). This group formed the core for the Dark Ages Re-creation Company. DARC would become my 'demonstration team' as I continued work on a number of the museum exhibits focused on the Viking Age Millennium (1000 years since Lief Eriksson explored Vinland / Canada).

> 2. Do you do any other re-enactment outside iron smelting?

See above.

I continue to participate in the SCA, but most often inside a DARC rules encampment placed inside a larger SCA camping style event.

DARC itself operates on a number of levels, outside of the ongoing iron smelting experimental archaeology series. We try to get together for at least one or two weekend workshops every year. These may be focused (like Neil Peterson's series of glass bead making experiments), or general 'come to the workshop and make stuff' sessions. These weekends sometimes include historic camps 'just for us'. On a normal year DARC will undertake at least one museum demonstration, which may range in scope from an afternoon in costume illustrating small hand skills to larger 'camps' which include 6 - 12 people and hundreds of replica objects.

Outside of early history, I also try to fit in at least one or two weekends of 'Black Powder' re-enactment. Here I typically work a museum's blacksmith shop, portraying characters ranging from 1760's through 1860's (depending on the museum requirements).

My wife and I had a loose association with the 'Ostvik' group out of Maryland.

> 3. Did your formal education pertain to the re-enacment you are

> doing now? Did you recieve degrees in history or any other

> related fields of study?

Likely in the way you frame that question, the answer would be no.

I undertook four years at a specialized art college. At that time I was intending on teaching at a high school level, so deliberately chose a wide range of subjects and media types to make my experience as wide based as possible. In a strange way, I had set myself up with an almost ideal background for my later museum work in the Viking Age. Using my exhibit 'World of the Norse' as an example, the hundreds of objects that had be be created for the exhibit ranged from forged weapons through to textiles, wood, leather, etc. So a wide exposure to many materials and traditional working methods has proved immensely valuable.

Technically, the only official certificate I have is my high school graduation. I have five years in total post secondary education (1 year in university level sciences), but no actual degrees. I have delivered four academic papers to date (one published and one pending).

In answer to a related unasked question - Yes, having at least a bachelors level degree would have been extremely useful. (I was almost denied entry into the USA on one occasion because it was decided I could not possibly be 'an expert' without holding a PhD!)

> 4. How did you learn the skills required to smelt Iron?

Understand that the process I am involved in represents a completely shattered traditional skill, one that was never recorded, and one for which the archaeology is extremely limited at best. The skills I have acquired so far are entirely learned through much error and repeated trials (something like 35 to date)

I owe a huge debt to Lee Sauder and Skip Williams, who had developed an interest several years earlier, and who where wonderful in sharing their own experiences. There had been some published information by a British experimental archaeologist, Peter Crew, but frankly, those papers proved more important as indications of what NOT to do. The entire field of historic iron smelting is almost brand new, no one had really undertaken any systematic attempts to determine these techniques before about the early 1990's. There has been a developing 'Iron Underground' in both Europe and North America, especially in the last five years. We all continue to work and pile up our successes and failures in an attempt to understand historic methods.

> 5. What brought about your initial interest in Viking (Age)

> re-enactment and specifically iron smelting?

Two Questions:

My very first awareness of the Viking Age can be pin-pointed to my seeing Tony Curtis and Kirk Douglas in 'the Vikings' back in the early 60's, when I was just a kid. Water that seed with Robert E Howard's Conan, books by Poul Anderson (who co-founded the SCA in the late 60's) and of course Lord of the Rings. I was so 'ripe for the picking' when I first stumbled across an SCA event (entirely by accident). I had been already investigating Celtic art, which lead to the rich design tradition of Norse art and artifact. The fit was immediate and ideal.

Iron smelting grew out of my professional work as an artisan blacksmith, coupled with my work for Parks Canada at L'Anse aux Meadows (see question 7). One other element - I had read an article by David Harvey from Colonial Williamsburg who claimed to have reproduced 'the first iron smelting in North America' based on Jamestown Virginia circa 1615. I * knew * that the first iron smelt was in Canada circa 1000 AD. This obvious distortion of history frankly just pissed me off. Something needed to be done about that...

> 6. Why do you continue to experiment in the field of iron

> smelting today?

I'm Crazy

I find the whole process both interesting and exciting. From the stand point of available archaeology, the remains found of historic iron smelting furnaces are like going to see Star Wars, and missing everything but the end credits (then claiming you understand the story line!). Each smelt is a complex and changing process, for which all that (sometimes) remains is just a small part of a destroyed piece of equipment. The only way any true understanding of the process can ever be made is through the mechanism of experimental archaeology (despite all the problems of applying current experiment to a historic reality). Second, the whole field is brand new. This work, carefully documented, can add directly to our compiled understanding of the past. This is not working over things looked at a thousand times already.

Third, this area is accessible. Practical workers can contribute just as much through their direct experience as trained academics can via theoretical research (likely more so!).

I'm Crazy

> 7. What role does your iron smeling play at L'Anse aux Meadows?

See the reference in question 5.

One of the critical pieces of the historical puzzle at LAM was the discovery of the remains of some kind of iron smelting furnace. (Smelted iron was completely unknown to the First Nations, its presence on site proved European involvement.)

Now, there are some differences of opinion about just how the discovery of a smelter fits into the larger story of Vinland. I have developed a different impression of the whole undertaking that the one originally suggested by Anna Stine and Birgitta Wallace. This concept is largely based on my own developing appreciation of the specialized technical skills required to actually get metallic iron from a bog iron ore, plus an understanding of the raw physical logistics of ore, fuel and smelter dynamics.

Iron smelting at LAM is part of the story of the habitation which Parks Canada has decided to illustrate. In 2001 they secured a corporate grant which allowed them to produce a reconstruction of one possible version of what the 'smithy' structure uncovered a LAM might have looked like. I was part of a small team assembled to consider the archaeological, technical and practical aspects of how to present this story to the public. A part of the week long session, I built and operated my first iron smelter, based on the best guesses of the archaeology and technology. Well, just about every thing we could have done wrong, was done wrong! (As I was to learn via repeated failures later.) My attempts to re-learn the lost methods of the Norse iron masters starts from this event.

One of the staff interpreters at LAM (who I trained) is Mark Pilgrim. Parks Canada has sent Mark on two further experimental smelts with the DARC team, as observer and enthusiastic participant. (2004 in Wareham and 2005 at CANIRON in Annapolis Royal NS) So in that way, I continue direct work and consultation with the working staff.

DARC is just starting discussions with Parks / LAM about taking part in the upcoming 50 year anniversary of the discovery of the site in 2010. Our hope is to return to LAM for our third mounting of a major living history event. A full iron smelt, using all Viking Age equipment, is part of our planned presentation.

> 8. How did you become involved with L'Anse aux Meadows?

I had been contacted by a local town (Orangeville) in 1992 when they were putting together a Medieval themed weekend festival. I managed to talk them into mounting a living history styled presentation based on the 'first days at Vinland - circa 1000 AD' (for 1993). The Norse Encampment presentation proved very popular with the public, and we repeated the presentation in 1994. I had designed a whole package, with background documentation, educational package, mission statement and such. I boldly sent copies of this material off to L'Anse aux Meadows NHSC - completely on my own initiative. I was a bit surprised when I received back an official request for a detailed evaluation of the program results.

This lead to Parks (through the local Tourism board) contracting me to provide a 10 day long 'demonstration' of a living history program at L'Anse aux Meadows. Neil Peterson (one of the other interviews) was part of the team of four, I bundled up with about 150 replica objects and trucked out to Newfoundland.

Parks was obviously quite pleased with the results of this program. The next year they commissioned the creation of a full interpretive program for the site. I researched and built the required objects, then trained a number of local people as the working staff. I returned for a second training session in 1998.

Since that date, I remain a consultant to the continuing 'Viking Encampment' program. Any given year I may be supplying replica objects and occasionally return to LAM for staff training.

> 9. What do you plan to accomplish with the grant that you applied

> for?

The specific grant you mention was in relation to my research trip in April and May of this year. (I see you have been reading the blog.). The dynamics of grants in Canada is quite different than the situation in the USA. I find myself between a rock and a hard place - applying to for Culture or Arts funding, but not really fitting the criteria for either. Although clearly history is part of Culture (and this is demonstrated as part of early Canadian history above) these grants are awarded to institutions, not individuals. As an independent consultant, I do not qualify. The Canada Council for the Arts was generous to help me apply under an obscure part of 'research by visiting curators'. The grant was approved, but did not rank high enough to get a piece of the limited funding. (The approval itself is extremely important, as it makes it possible for me to apply into the future.)

So, the purpose of the applied for grant was to offset the cost of travel to 'the Iron Smelting Seminar at Thy', a gathering of mainly European experimental iron smelters. I knew most these people from e-mail correspondence, but this was the first time we had met face to face. For a week we made iron all day, then talked about common problems and insights all night (on about four hours sleep a night!)

The importance of the grant was to support the raw cost of the trip, about $2500 overall. I had some money saved up to replace my ageing truck. Maybe some other year...

> 10. What do you feel people can learn from iron smelting and

> Viking (Age) history in general?

Iron smelting is specialized, and the information gained from it will also best apply to a specialized audience.

As archaeologists can only examine weathered remains from the last stage of a multi-staged process:

- The first thing our current experiments can illustrate is all the other parts of that hours long sequence that end in the evidence they uncover.

- By carefully recording our work areas, we can help archaeologists determine just what the physical remains they uncover can imply.

- As we develop working experience with the process of smelting, we can provide information about required equipment and raw materials. This in turn can be related to things like production rates and social organization.

- We have been setting aside furnaces and allowing them to naturally age, recording this process photographically. This can provide a bench mark to understand excavated remains.

Viking Age / Norse history is important to all of us - as any of our history is important. 'Those who disregard their pasts are doomed to repeat its failures.' Also quite importantly, how the heck can you figure out where you are going if you don't know where you came from?

In Western European culture, thus North American culture, a surprising amount of our cultural framework is based on the Norse. Our days of the week: Tuesday through Friday are all name days of Norse gods. Our tradition of democracy owes as much to the Althing of Iceland as it does to the Greeks.

One extremely important element of Norse history is the root causes of the sudden explosion out of Scandinavia in the late 700's - and the collapse of the Greenland colony in the early 1400's. Both are at root effects of shifting climate, global (or at least regional) warming in the first case and the sudden reversal of the Greenland current in the second (which caused the 'mini-ice age' which had such an impact on all of the Western Hemisphere). The death of the Greenland colony is also a warning about a once adaptable people who refused to change when disaster came upon them. (Way too much like George Bush's America for anyone not to see the parallels.)

Besides, the Viking Age is so cool!

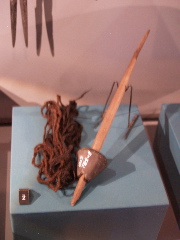

> 11. What types of things do you create when you smelt iron?

To date, I have been so focused on just making the iron blooms themselves. Your first good quality blooms are like children, you have laboured so hard to produce them and each one is special. I have taken a couple of fragments down through the next step - bloom to bar. This is also a considerable physical effort, with its own set of new problems to solve. In the fall I did make my first two art objects out of my own bloom metal. This was a knife blade (investigating the effect of carbon layering to generate patterns) and a small sculptural piece ('Offering Bowl'). I have plans for another, larger container, in this case a funeral urn. I have been given pieces of blooms from Mike McCarthy and Lee Sauder (with differing carbon contents). The plan for these is to forge up a demonstration piece that shows the process of bloom through to pattern welded sword. (Intended for a teaching tool for Neil Price at the University of Upsula.) I hope to be able to contribute both blooms and worked 'currency bars' for future museum displays.

Some of the new workers in the area of iron bloomery furnaces are knifemakers. They have been trading on the unique nature of the self made iron in the blades they sell. I personally consider this a bit of showmanship, and really not what the field is about.

> 12. What role would you have played in Viking (Age) society as an

> iron smelter?

Big Question!

Many archaeologists have been of the opinion that 'almost everyone' in the Viking Age was able to effectively smelt their own iron. I have found that those (few) who are following our experimental work have revised this (incorrect) opinion. Making iron from dirt is a highly specialized task that requires considerable experience to undertake to a positive result.

To my own opinion, the Iron Masters of the Viking Age would have been one of two types. There would have been those who travelled, being hired by individual extended family farm complexes to produce iron on a seasonal basis. The iron produced would have been used for the farm requirements, with any excess being sold for cash. I would expect the payment to the iron master to be silver and / or a share of the metal produced. (There is a PhD in the study of this for someone!) The second type is well documented in the remains of major iron smelting works, often that remain in production for generations. Here the iron masters are fixed, with the knowledge being passed down from father to son.

One important element to consider is that the iron master is not the blacksmith. The blacksmith in the Viking Age would purchase the required raw metal in the form of standardized currency bars.

Iron forms the core of the Viking Age. Although the 'personal load' of iron per individual is small by our modern standards, iron formed the rivets for the ships, the working tools supporting daily life, and of course the weapons so feared by the rest of Europe. In terms of the times, the Norse were relatively iron rich, and showed great skill in its working into objects. Without the iron master, this would not be possible. To balance this utility, iron was smelted almost always at the source of the ore, often remote from the rest of the population. The iron master held certain dark secrets, directly manipulating earth, fire and air to create the treasure of workable iron metal. Easy to see the connection to the legends of the Dwarves, tolling in secret under the mountains to create objects of magical power.