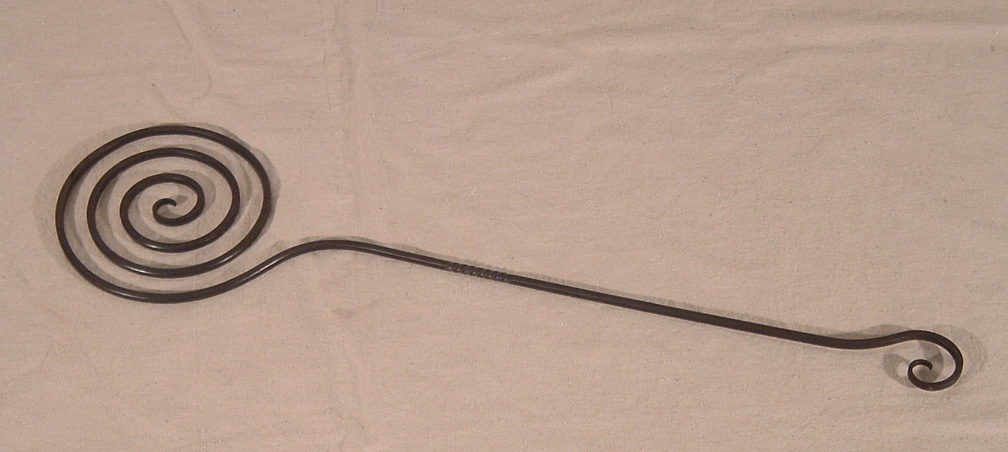

This tale starts with the following image, seen on the Wareham Forge web site:

The specific objects illustrated here I created for the feature film Outlander, back in 2006. The commission included a cauldron hanger and cauldron, plus the set of cooking tools seen above. There was also a 'slave chain'. The chain and the cauldron set would both be clearly seen in the final film. (1)

So...

It appears that the image above has been shot around a fair amount over the world wide web. Usually with all the citations removed. (2) Particularly via Pinterest, which appears to be intentionally designed to remove the original source information. The image seen on Pinterest actually appears to be located on Tumblr : here

Next element to this story is that one of those Pinterest images got posted up to a special interest group on Facebook (quoted here with the links and names removed) :

posted in

AUTHENTIC VIKING FOOD

|

Greetings

original foodies

|

Because of that posting to face book, I have had some people track me down over the last week, asking for the artifact reference.

Have you ever had research you undertook years ago come back to haunt you?

In this case decades ago!

" It's in one of these books - one of them - someplace... "

Well, after about three hours and dozens of reference books checked page by page, the answer to that is 'not really'.

My original production notes for the Norse Encampment (going back to the early 1990's) gave me this (single) reference:

Spiral Iron - Berger, Norway; in Universitetes Oldsaksamling, # 15788

(You might note that there is a typo there, long un-corrected - it should be BERGEN) (3)

The description I provided was:

This cooking tool would have been used for grilling meats. This item appears to have been much less common, with only a half dozen or so samples surviving. Most of the artifacts are quite small, with the diameter ranging from 6 to 17 cm, with the average being around 13 cm across. This is likely because of the large length of iron rod needed to make a spiral. Although the reproduction is only 15 cm in dia, forming it required about 70 cm of rod. One of the major domestic meat animals for the Norse was sheep, and port was likely more commonly eaten than beef. In both cases the excess fat would drip through the open coils during cooking.The only drawing of my own I can find is one intended as the production drawing - my visual notes for creating the replica for the Encampment program. An such, not a drawing from an artifact, but at best only an 'interpretation' : see Iron Objects 2 on the Norse Encampment documentation (Of interest may be that the original spelling mistake may go back to this hand written note.)

All that digging did turn up this :

|

| Original drawing 4 3/4 inches wide - click to expand |

For this next bit, I have to thank Christie, known as the Viking Answer Lady. Over the years I have come to respect the depth of her research and understanding. I had sent her a quick e-mail asking her if she knew an artifact source she could quote me :

Actually, I found a couple of examples in museum website data galleries and sent them to you a while back, since I had noticed that uy'all didn't have pics on the Forge website. Hmm. Let me look...

Aha! Here you go:

http://www.unimus.no/arkeologi/#/detailsView?search=C580

http://www.unimus.no/arkeologi/#/detailsView?search=C15788

So here is what you will find there:

|

| Object 580 - description |

|

| # 580 - image altered to increase surface detail |

|

| # 580 - Field Drawing (?) Note resemblance to 'page 156' reference. |

|

| Object 15788 description |

|

| # 15788 image |

580.

A Toast (?) ; of iron; formed by a long, flat iron plate of about 1 T's (inches ?) Brede (breadth) (breadth is ei (not) everywhere DC (uniform?) ), which is bent in spiral form, so that the Forms a round surface of approximately 6 Tr's (inches ?) on an average, and then go straight out as a Haandfang (handle ?); its length is approximately 5 Tr (inches ?). but a piece seems to be disconnected. (Avb. R. 429).

Gravfunn from the early Iron Age. Berger (gnr. 14-16), Aurskog p. og pgd., Akershus . and PGD., Akershus.

15788.

A remnant of a spiral formed grating av iron, lik(e) R. 429th . Both the most audiovisual (remaining?) shaft and the inner part audiovisual (remaining?) coil is missing.

What you see from the artifact samples:

Small diameter (# 580 at 15 cm)

Formed of flat profile stock

Forged to a fairly tight spiral (not given or scaled for #15788)

No detail on original handle terminal, length

So at least some of my original Encampment description bears relationship to the artifacts.

(My memory somewhat intact - I did not make this all up!)

One glaring early interpretive error I note now:

The concept of allowing fat and grease to run off is an extremely modern, Canadian, observation. If anything, in the cold northern climate of the Viking Age, fats would have been retained and consumed for their high energy content.

I also received this question this week:

From Joanna:To that question, I draw an absolute blank. I am not aware of any food artifacts as you suggest. (But I'd guess the Viking Answer Lady knows!)

I was gifted with one of these irons a number of years ago. At the time I was told that there had been a find of petrified bread rolls/patties/some kind of baked bread that were marked on the bottom with spirals the size of this iron.Do you have any idea of where any articles about this may be?

I do make general replicas of all these Viking Age cooking tools for sale off the Wareham Forge web site : see NORSE TRADE GOODS

I can make not only the basic cooking irons and trammels, but more elaborate pieces like the Oseberg Tripod, the Mastermyr Pot and Mastermyr 'cooking' grill. In the past I have created pots and cauldrons in antique wrought iron, steel, copper and brass / bronze - as well as decorative forged cauldron hangers.

Why not get these from the original source?

1) For a full look at my work on these props for Outlander, see:

Description on the Wareham Forge

Earlier Blog Postings

2) Try this experiment : Go on to Google Images / search using ' spiral, cook, viking '

What I see is that only the first eight images actually are of cooking tools (and even then, #3 is of a spear.) Five of those eight are images of various replicas of this spiral cooking tool that *I* have made over the decades. *

NONE are actually artifacts - and I have not been able to source an artifact reference via Google Images.

The other two images are of a version by 'Welandsmithy' :

You can see that version is made from round profile stock. This is certainly not historically accurate, and has surely been chosen for the much easier forging effort on the part of the blacksmith involved.

About # 20, you will find an image of the version by 'Iron Leaf Forge'

What has been done here is that round stock has been forged to the spiral, then pounded flat. This results in the irregularities seen. Once again not the historic method.

3) What I find particularly humorous about this, is the written description given (and not credited btw) :

" Based on the few fragments found in Berger, Norway this cooking tool was thought to be used for cooking fatty meats. "Note the repeat of my original typing error?

Honestly, I personally find the way most people pass off work as 'replicas', or even worse, 'reproductions' fairly annoying - and certainly without accuracy.

Its also a wee bit insulting that other metalworkers are selling lower quality versions of my own work - obviously using my research without doing their own.

* I do note that because of the 'custom search' method that Google is using, your personal results might vary!