First take a look at the construction (mind you not TOO close!) on this bellows:

For this first version of a VA bellows, I used strips of willow, split from green wood, then soaked, bend to shape and nailed. The Wood bands are really what holds the leather tight to the planks. Fewer nails are required. (The ones you see there are the 'hand wrought head' style ones from Tremount - I did not make them.) Larger nails possed real problems with potentially splitting the wood. I did use a modern silicon caulking material to air seal the leather. Historically a hide or other organic glue would have been used. This substitution was made because I knew the bellows would be stored and used in quite damp conditions (at L'Anse aux Meadows NHSC).

What my latter versions used was smaller (and a lot more) regular carpet tacks. There are not any existing carpet tacks from the VA of course. What I have seen is only 'close' - related to the Sutton Hoo Burial (Saxon, circa 625 AD). In the construction of the lyre, small triangle shapes of copper are used as tacks to hold the top plate to the frame. It would be possible to make small tacks by starting by forging a strip of iron. Then triangular wedge shapes could be cut with a straight chisel. To hold leather (or a thin strip of wood) you would need some kind of spread out head to the tack. If you had previously made the right size and shape heading tool (punch a correct shaped hole into a thicker bar) you could likely do the heading cold. Please note that I have never come across any such tacks in the artifact record (But as Bruce says "absence of evidence is not evidence of absence").

From a design stand point, there are a couple of things wrong with the mark one bellows (first image):

- One is the proportion of intake to outlet holes. Further experimentation showed that better results were achieved with a larger intake - something like a ratio of 4:1. With a standard outlet tube size (determined by examining artifact tuyeres) at around 2.5 cm interior, that puts your inlet hole at about 10 cm diameter. This works well with a simple leather flap valve (a circle held at two opposing sides).

- It proved completely ineffective and unnecessary to have any kind of valve on the down stream side. The simple leather tab valves seen in the image above where latter pulled out. With a correctly designed Y tube and the proper proportion of inlet to outlet, plus the correct operator technique (!), no downstream valve is required.

- Although the small tab style handles are suggested by the only clear historic depiction of a blacksmiths bellows in operation (see bellow), it proved a quite ineffective style. Not surprisingly, most users ended up gripping the side of the top plate - just as seen in the source illustration.

- the hinges here are heavy leather backed up with two strips of wood. I owe Kevin from DARC the inspiration on this, as his first bellows (made for metal casting) used two nailed down metal plates to re-enforce leather as hinges.

Shows a latter reconstruction. This basic pattern has become my working standard. There are a number of these out there in various displays and working demonstration use. That image also shows the correct set up of a VA ground forge with bellows stone and flexible coupling leather Y tube.

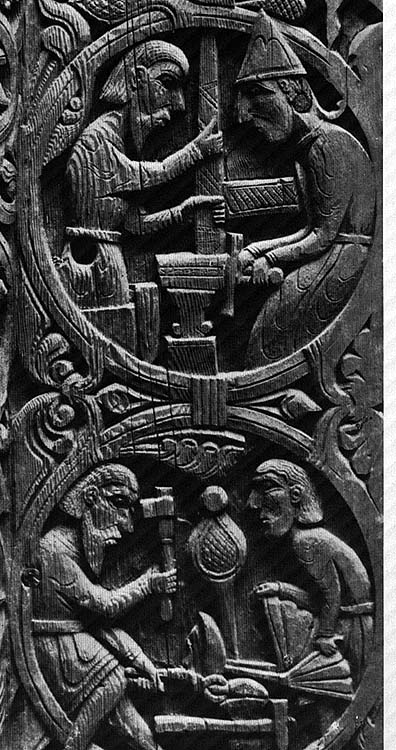

Is the main historic reference for any kind of bellows from the Viking Age. It is dated closer to 1150 and from the Hyllestad Church in Norway. There is a second carving - a top down view on a rune stone from Ramsund Sweden - but is more cartoon like and not directly associated with a human figure (no way to get measurements).

I have made a fair effort in trying to track down any actual physical remains of a bellows from the Viking Age (or anything before about 1200.) So far I have not found reference to a SINGLE artifact. What we have is only the two carved images above. Every time I hear about a bellows, it turns out to be a late medieval (or later) unit found inside a site with a much longer occupation history.

** If ANYONE has any hard evidence of an artifact bellows from the Viking Age - PLEASE send me an image or a publication reference!! **

What we do know is that larger and more prosperous farm steads from the VA often have special built small workshops with evidence of a forge within them. There is of course no way to prove if a bellows and anvil were owned by the farm - or supplied by traveling blacksmiths on a seasonal visit.

1 comment:

Hey Darrell, my name is Josh Lane and I want to learn from you at the Wareham Forge this year.I will send my deposit tommorrow, cause I don't want to miss my opportunity, but am wondering when your April, basic blacksmithing classes are? I will become a bladesmith/blacksmith, it has been my dream and I am not wasting any more of my life settling. I want to take bladesmithing and blacksmithing courses so please send me the dates at you earliest convenience, and if the possibility exists of taking basic bladesmithing and blacksmithing back to back?

Post a Comment