In an earlier post I had shown the source for the the Mastermyr tools ( HERE ) - my copy of (the quite excellent) 'The Mastermyr Find' by Arwidsson & Berg. This is an essential source for anyone interested in tools, blacksmithing or work working in the Viking Age. (Check a google search for 'Norm Larsson Books' to get a copy.)

The Mastermyr adze is a bit of a problematic tool - for the Viking Age proper. It was on the strength of this object that the find was later re-evaluated and the deposit date changed to closer to 1150 AD. This is a light single hand tool. It is described as having an edge width of 17 cm, the total weight of the head is only 700 grams (as found). The eye is roughly 3 cm long which would not allow for a very robust fitting at the handle, especially considering the blade width.

The tool may have actually been used as a kind of large 'slick for smoothing already axe shaped timbers. This also helps explain the overall light construction (weight and especially lack of strength at the eye). The tool may actually be intended to be used more like a big wide chisel. You would place the blade on the surface to cut, then strike the peen end with a mallet or hammer, driving the cutting edge along the surface of the wood. Depth of cut would be controlled by levering the handle. The extensive mushing over of the peens on both the Mastermyr adzes certainly suggests this use.

My reconstruction is pretty close to the 'new' weight of the original, working out to a total of 800 gm. The blade length is pretty close, at 19 cm, with the total length at 18 cm. It was formed from two pieces forged welded together. The block of the eye is lap welded to strip for the blade. This strip was itself created from a piece of spring steel lap welded first to a mild steel body.

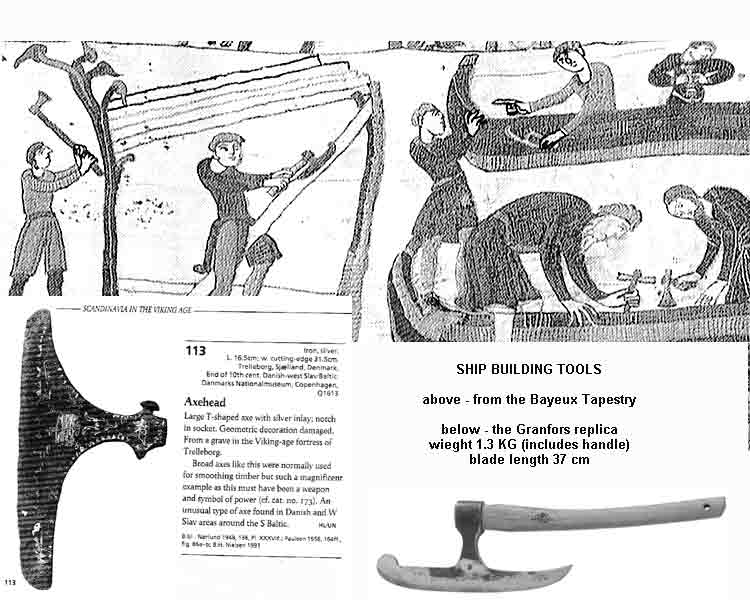

One of the most problematic tools in the entire set is this one - the large T shaped broad axe from the Bayeux Tapestry. As far as I have been able to tell, there is on a surviving example of this exact tool. My reference sheet (above) shows the two images from the Tapestry, which of course lack little detail, and don't even agree to size or use. I was able to find one related artifact, but only as a very small image. The (quite excellent!) Gransfors - Bruks company makes a replica of this tool. I did also lean on this reconstruction for my own version.

The resulting tool is heavy, at 2.25 KG. The blade is 45 cm in length and 18 cm total width. Based on my experience with Settlement Era broadaxes, it is fitted with a 3/4 length handle (55 cm long). Unlike later broadaxes, this one has its edge with a central V bevel (not flat to one side). I did leave the eye slightly canted off the centre line of the blade, so the hands would clear the timber on right hand use. (I don't know if this was a feature of the original tools.) Like the adze above, the tool is made from two pieces. In this case the blade is made from three bars, with two pieces of mild steel encasing a full spring steel core. The eye block was here slit back to open a V shaped slot into which the blade was forge welded.This all was extremely hot and heavy work!

The resulting tool is heavy, at 2.25 KG. The blade is 45 cm in length and 18 cm total width. Based on my experience with Settlement Era broadaxes, it is fitted with a 3/4 length handle (55 cm long). Unlike later broadaxes, this one has its edge with a central V bevel (not flat to one side). I did leave the eye slightly canted off the centre line of the blade, so the hands would clear the timber on right hand use. (I don't know if this was a feature of the original tools.) Like the adze above, the tool is made from two pieces. In this case the blade is made from three bars, with two pieces of mild steel encasing a full spring steel core. The eye block was here slit back to open a V shaped slot into which the blade was forge welded.This all was extremely hot and heavy work!

3 comments:

Does the action of this broadaxe cause the handle to break routinly? Is this broadaxe intended to be used differently than modern broadaxes?

Michael:

I can only offer some limited observations.

First, you are correct to ask if the T shaped broadaxe is used differently than Settlement era versions. The answer to that is 'most definately'. This VA tool appears to be used for fine shaping of timber - not heavy hacking to square logs like the Settlement style.

As to just how durable either the tool or handle may be, I have no personal experience to guide me. The replica shown was used by the interpretive staff at LAM to build a small boat (faering) to good effect - with no reported problems. I also know this type of tool was used extensively at the Viking Ship Museum for their various replica ship building projects. Perhaps contact them directly?

Sorry, but I think I must correct you on your comment regarding the use of the "Adze". It was not used as a chiesel but as an axe for levelling cloven planks for buildings and ships.

You use the adze from a position 90 degrees in front of the the cloven plank, cutting downwards with a two-hand grip, making a long chip. The blade must be a little bit curved. This chareteristic cut is found in lots and lots of planks from the Viking age, fx in Haitabau (Hedeby).

It is correck, that the eye is small. Therefore you will use a very tough wooden handle, made from fx. hawthorn. My own adze had a handle made from ash root.

Post a Comment