Richard wrote:

-- what are the archeological dimensions I should be aiming for?

-- am I burying it in a bank or should it be free-standing?

-- given the strong prevailing winds here, should I be looking to place it in a sheltered location, or would careful orientation help create better draw

|

| Suggested build of the original Hals Furnace |

1)Link to the full report on the Hals furnace:

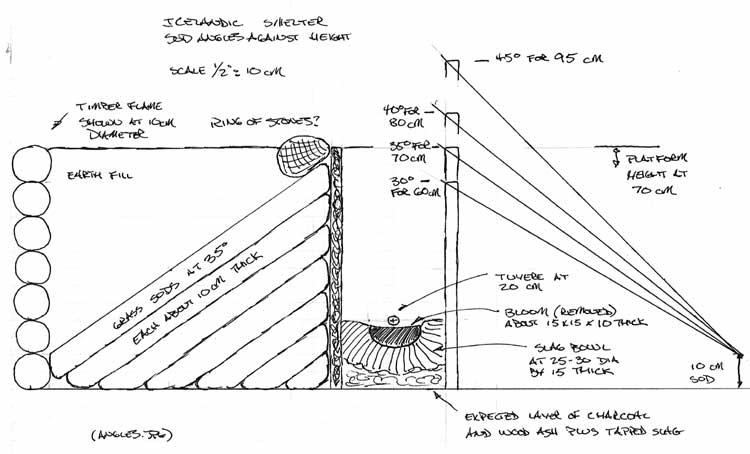

The full construction is a cone of sod roughly 2 meters in diameter, standing roughly 70 cm tall. There is a 30 cm diameter cylinder down the centre. The suggestion is that this cone was surrounded by a box made of timber (alternating logs?) - with the gap between the timber and the sod filled with earth.

2) In effect the construction above is like a free standing bank. The box of earth makes a stable work platform on the top.

One important question is :

"How wide does the sod band need to be."

In use, the sod is in effect taking the place of the thick clay cob walls we have been building to date. The grass roots are creating the stability - during the firing process. The interior wall of the cylinder had a thin (3 cm suggested) layer of clay like marl as a fire proof coating. The fact that the stacking of the sods creates a series of diagonal lines - running downwards away from the interior - is going to keep hot gasses from seeping out of the grass layers.

A team from Iceland, under Margrét Hrönn Hallmundsdóttir, had run a version of the Hals system last year. Margret has worked with Kevin Smith, and she and I did converse a fair amount before her experiment (her first full iron smelt).

http://www.warehamforge.ca/ironsmelting/HALS/angles.jpg

The furnace they built (at least from the photos), was more a square, flat layered stack of the grass sods. They also made some other departures from the archaeology at Hals. I thought the main one was that they built a chamber of stone blocks for the bottom third of the furnace (basically square). The construction they used was using the sods more like flat stacked bricks.

It has occurred to me that we might do a first test by either partially earth banking the construction - or putting the whole inside a smaller plank constructed wooden box.

The first would allow us to undertake a top extraction - which is suggested by the Hals evidence (slag bowls in place). The second would be simpler using a bottom extraction.

Something to take a look at would be the way the team from Tranamo Sweden group had built a semi portable demonstration furnace. They had used a cylinder of fire brick held in a 45 gallon drum - this surrounded with a wooden box that they used earth to stabilize.

|

| At Heltborg, Denmark, 2008 |

On alignment to the wind:

It might be nice to have the wind going from our backs across the front of the furnace - or from side to side. At Wareham the prevailing winds go from the rear of the smelter towards the workers. This only occasionally pushes the heat into our faces (singed beards). In terms of providing air blast - it would only be the rare day this would really be useful. A bellows or blower system is still in play here.

DARC has undertaken a number of smelts in a series leading up to a full reconstruction of the Hals Iceland system. You can find this work documented on the full Wareham Forge IRON SMELTING web site

No comments:

Post a Comment