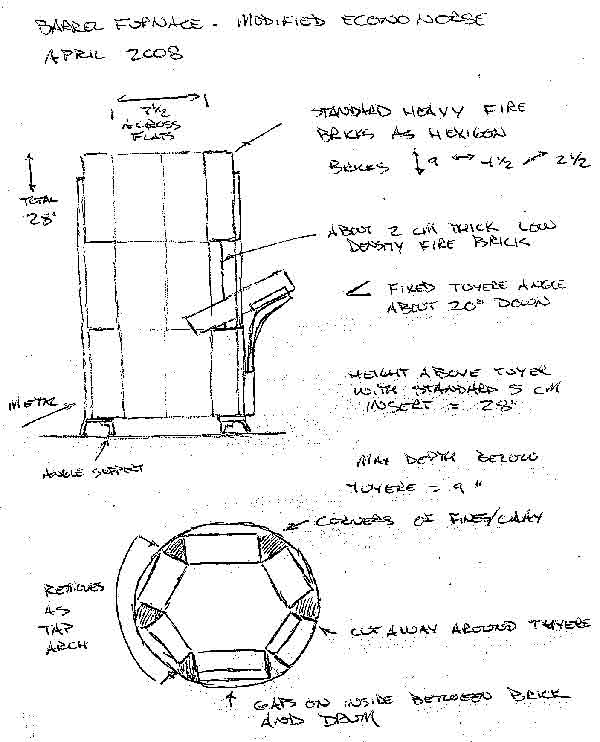

The drum was just about exactly the same size as a hexagon arrangement of standard hard bricks - stacked the normal three sets tall. The result is a smelter containment that is roughly 20 cm internal diameter, but still at the normal plus 40 cm above the tuyere.

The drum was just about exactly the same size as a hexagon arrangement of standard hard bricks - stacked the normal three sets tall. The result is a smelter containment that is roughly 20 cm internal diameter, but still at the normal plus 40 cm above the tuyere. I cut the required holes and ports into the barrel, and welded in some external and internal fittings and supports. On the lower view, you can see the removeable 'hatch' that covers over two of the lower ring of bricks which can be pried loose for either a large tap arch or for a possible bottom extraction. Although these bricks are also backed up with the clay and charcoal fines cobb, they were wrapped with paper first to make removal later easier.The section of barrel that was cut away to create the hatch is held back in place by a length of flat bar which also forms a simple handle.

I cut the required holes and ports into the barrel, and welded in some external and internal fittings and supports. On the lower view, you can see the removeable 'hatch' that covers over two of the lower ring of bricks which can be pried loose for either a large tap arch or for a possible bottom extraction. Although these bricks are also backed up with the clay and charcoal fines cobb, they were wrapped with paper first to make removal later easier.The section of barrel that was cut away to create the hatch is held back in place by a length of flat bar which also forms a simple handle. A rectangular hole was cut the same size as the brick that holds the tuyere and sits above it. This brick is made of low density fire brick which has been cut in half to about 2 cm thick. If past experience proves correct, this material should radiate excess heat on its outside surface - and reduce erosion.

A rectangular hole was cut the same size as the brick that holds the tuyere and sits above it. This brick is made of low density fire brick which has been cut in half to about 2 cm thick. If past experience proves correct, this material should radiate excess heat on its outside surface - and reduce erosion. Looking down from the top, the cobb packing holding the bricks into place can be seen. The packing is a rough triangle in the gabs of hexagon pattern of the bricks. An air space has been deliberately left between the flat sides of the bricks and the curvature of the circular barrel. The hope is that this will allow some of the excess heat to bleed off into the gaps.

Looking down from the top, the cobb packing holding the bricks into place can be seen. The packing is a rough triangle in the gabs of hexagon pattern of the bricks. An air space has been deliberately left between the flat sides of the bricks and the curvature of the circular barrel. The hope is that this will allow some of the excess heat to bleed off into the gaps. Hopefully the smelter will prove to be reusable. The reduced size and the hard support provided by the barrel should make the furnace body easy to move on a two wheeled cart. Although the fire bricks make it fairly heavy, two people should be able to pick it up to load it into a vehicle.

Hopefully the smelter will prove to be reusable. The reduced size and the hard support provided by the barrel should make the furnace body easy to move on a two wheeled cart. Although the fire bricks make it fairly heavy, two people should be able to pick it up to load it into a vehicle.The proof of the design will come on Sunday, when this is the furnace that will be used for the second test of the bog ore analog.

1 comment:

Has the deluge in your yard subsided yet?

(By the way, hi! I don't know if you remember me from the classes you used to teach at Castle Frank on Saturdays - - ? Just found your blog a few days ago, but I've linked to your Forge the last few months.)

Post a Comment