... was just debating about making my version of an iron age mirror then I found the mirrors you have made... was just wondering if you could tell me how you went about etching the pattern on the back of your mirror, I'd like to do it using iron age techniques is that how you did it? I have read that they may have covered the mirror head in wax then scratched out the pattern but I don't know what solution they used for the etching. what technique did you use?Aaron - Suffolk in England

The actual Celtic Iron Age artifact that inspired this specific design would have been *engraved*, not acid etched. A fine bladed tool (like a small chisel) would have been used to either scratch or cut away a thin channel into the bronze surface. There may have been some kind of ink rubbed into the pattern to accent it, but with the age of so many of these artifacts, its hard to be certain.

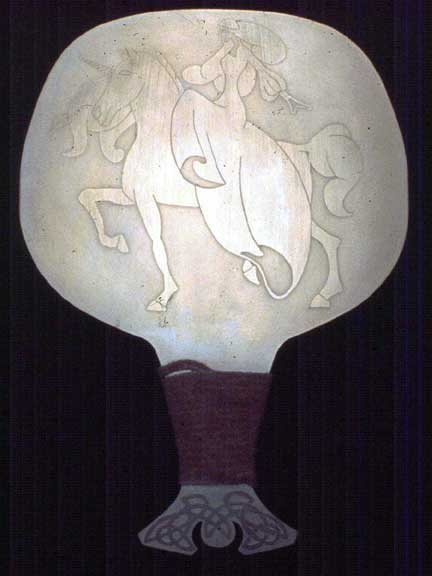

Image from www.celticmirrors.org

This site has descriptions and images of a large group of Celtic bronze hand mirrors.

This site has descriptions and images of a large group of Celtic bronze hand mirrors.

I had done a considerable amount of work with acid etching as a decorative technique back in the 80's. This actually was an application based on what I had learned print making in college.

Bad news is that as a *historic* technique, the earliest use of true acid etching to produce decorative designs can only be traced back to the 1300's. The earliest objects I had been able to find using etching to make patterns on their surfaces were on the blades of pikes and halberds from Italy. These had used bees wax as a solid surface resist, through which a needle had scratched to expose the bare metal. The etching process produced simple line designs. The technique became more common into the Renaissance.

The problem lies with the creation / discovery of actual chemical acids. There is certainly a connection with early Alchemy (which is how many of the discoveries that underlay modern chemistry came about). Before the Middle Ages proper, the only acids available were organic based ones - basically vinegars. Although those organic acids could certainly discolour metals, they were not active enough to usefully cut away at metal in the way required for creation of durable decorative patterning.

My base method on my own work is to use a liquid tar resist, painted on as fine lines and larger areas. When the resist drys, then fine detail can be scratched in with a needle probe. I have used a number of different acids in the past, based on availability of the chemicals and solutions suited to specific metals.

A general description on acid etch method can be found on an earlier blog post.

The main exception to this may be the case with Northern European pattern welded blades (recently also called 'composite twisted core'). Some of the individual artifacts have extremely complex sets of twisted and straight sections to the twisting, the sword from Sutton Hoo being the most elaborate example. Its hard to imagine there would not have been some attempt to accentuate such difficult and careful craftsmanship. Although immersion in vinegar would certainly stain the layers to highlight them, this would be at best a surface discolouration and not a true acid etch for depth.

Modern practice for finishing layered steel blades is to use various acid solutions to expose the fine lines of the layers created in the forging and finishing. As different metals will respond differently to both the same, and also differing, acids, often more than one acid bath may be used.

More information (and samples) of my past work with layered steel blades can be found on :

Bladesmithing from the Wareham Forge

Gallery of past Bladesmithing work

Bladesmithing from the Wareham Forge

Gallery of past Bladesmithing work

No comments:

Post a Comment